BF-114W. BF-114L

WAFER TYPE, LUG TYPE, CORROSION RESISTANT.

BODY: GGG40, A216-WCB, CF8, CF8M

DISC: PTFE/PFA/FEP LINED, SUS, ALUMINUM BRONZE

STEM: SUS

SEAT: PTFE/RTFE/PFA/TFM

CONN: ANSI 150LBS, JIS 10K, PN10/16

INSPECTION & TESTING: API 598, EN 12266

MOUNTING FLANGE: ISO 5211

SIZE: DN40-DN400 (1.1/2”~16”)

TEMPERATURE: -40℃ ~ 180℃

OPERATOR: LEVER, GEAR, PNEUMATIC, ELECTRIC ACTUATOR OPERATED

(BF-114W / BF-114L) LINED BUTTERFLY VALVE

CONCENTRIC TYPECORROSION RESISTANT

MODEL:

BF-114W WAFER type

BF-114L LUG type

* Please

specify the required Model No. when ordering

*

Optional: Lever Handle, Gear Operator, Pneumatic and Electric Actuators

* Valve Designed to MSS SP-67, API 609, ISO 5252/20

* Face to Face: API 609, ISO 5752, EN558-1

* Suit for:

ANSI B16.5, EN1092, JIS B2220

* Inspection

& Testing: API 598, EN 12266

* Mounting Flange: ISO 5211

* Material: GGG40, A216-WCB, CF8, CF8M

* Body

Configurations: Wafer and Lug

* Range: DN40-DN400 (1.1/2”~16”)

Applicable:

_Chemical Processing

_Petrochemical

_Pulp and Paper Processing

_Solid handling

_Purification Plants

_Pharmaceutical Industry

_Food Industry

_Textile

_Highly corrosive gas, liquid, slurry, or powder

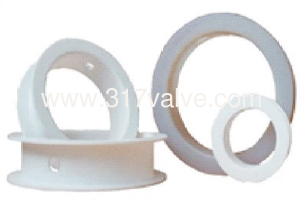

- Disc Lining - - Seat Liner -

(BF-114W / BF-114L) LINED BUTTERFLY VALVE

CONCENTRIC TYPE CORROSION RESISTANT

MODEL:

BF-114W WAFER type

BF-114L LUG type

SUIT FOR: ANSI B16.5, EN1092, JIS B22200

INSPECTION & TESTING: API 598, EN 12266

MOUNTING FLANGE: ISO 5211

OPERATED: LEVER HANDLE, GEAR OPERATOR, PNEUMATIC OR ELECTRIC ACTUATORS

SIZE: DN40-DN400 (1.1/2”~16”)

Material Specification:

1. DISC: PTFE/PFA/FEP LINED, SUS, ALUMINUM BRONZE

2. STEM: SUS

4. SEAT: PTFE/RTFE/PFA/TFM

5. WASHER: PTFE

6. O-RING: FKM/VMQ/FKM with PTFE

A lined butterfly valve is designed for control and the isolation of aggressive media. A fully lined valve is highly recommended for abrasive and corrosive applications where require reliable performance, drop-tight shutoff, constant torque, and no maintenance.

Lining Material

We use virgin resin of a well-known brand to produce its PTFE, PFA, and FEP fluoropolymers. Especially for lined valves, factors including liner thickness, resin quality, and fabrication expertise always are more significant to affect valve performance and its service life.

Seat Liner

* Materials shall be PTFE, PFA, and FEP

* Molded and machined with minimum 3mm nominal thickness.

* Optional TFM liner available for extremely demanding applications.

Disc Lining

* Fully lined with PTFE or PFA

* Encapsulated with a min. 3mm thick PTFE or PFA